commercial water softeners

Commercial water softeners

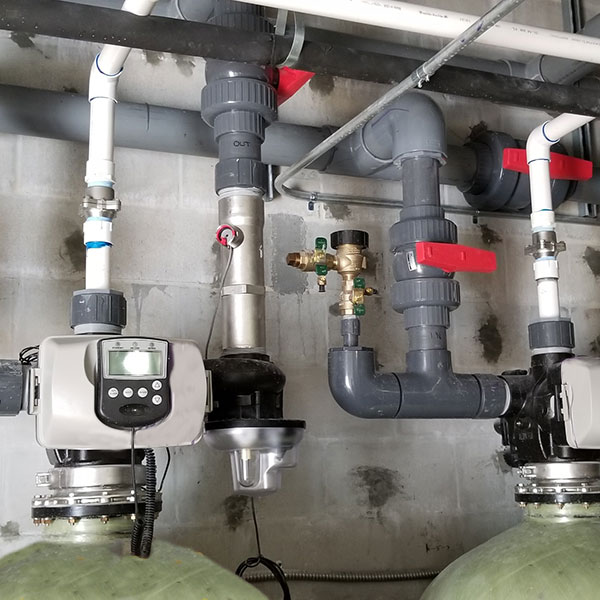

Major components of our Commercial water softeners include our metered control valve, designed to provide greater efficiency; pressure tank; brine tank to contain the water softener salt; ion exchange resin; gravel under bedding to provide even flow distribution; hub and lateral bottom distributor; and water softener salt, used to strip hardness minerals from the resin beads. Systems are manufactured in the USA and assembled in Ocala, Florida. Valves, tanks, resins, filter media and carbons are NSF certified and meet all performance requirements.

Our engineering department is eager to assist you with your commercial and industrial water softener requirements. All water softeners come with USA manufactured valves, NSF certified mineral tanks, gravel under bedding, riser tube, distributor and brine tank. Systems with 1.5”, 2” and 3” valves come with hub and laterals to proper flow distribution. Systems are shipped unassembled on pallet.

How Water Commercial Water Softeners Work

The process whereby hardness minerals are removed is described below:

- Water flows through the resin bed.

- As this occurs, hardness minerals (Calcium & Magnesium) are attracted to the resin and are removed from the water.

- Eventually, the resin reaches its capacity and the resin must be cleaned. (This process is called “regeneration”.)

- The control valve initiates the “cleaning process”, based on gallons used (not time) to limit salt consumption.

- During the cleaning process, brine water flows through the resin bed, removing the water hardness minerals because they are attached to the sodium in the brine water.

- Finally, the resin is rinsed so no salt gets into the water entering your facility.

Cycles

Regeneration cycles are described below:

Backwash

This is an upward flow to remove any particles which have accumulated in the softener tank and to refresh the resin bed.

Brine draw

This important step is when brine water flows through the resin to remove the hardness minerals. During this cycle, hardness minerals become unattached from the resin and are attracted to the sodium, contained in the brine water.

2nd backwash

During this up-flow cycle, salt and hardness minerals are rinsed off the ion exchange resin.

Rinse (downflow)

This is an additional cycle to make sure the salt is thoroughly removed from the resin.

Refill

During the refill cycle, water is added to the brine tank so there will be a sufficient amount of brine water for the next regeneration cycle.

Service

This is when water flows through the softener to provide soft, conditioned water..

VIEW SOME OF OUR RECENT WORK

Commercial Water Softeners Backwashing Filters Valve Types

| Valve type | Metered |

|---|

| Valve sizes | 1”, 1.25”, 1.5”, 2” and 3” |

| Pipe fittings available | ¾”, 1”, 1.25”, 1.5”, 2” and 3” |

| Regeneration method | Down flow |

| Riser tube size | 1.05”, 1.25”, 1.5”, 2” and 3” |

| Drain line fitting | ¾” male NPT |

| Drain line tubing | ½”, ¾” or 1” |

| Brine line | 3/8” quick connect |

| Supply voltage | 120 V AC |

| Supply frequency | 60 Hz |

| Output voltage | 12 V AC |

| Operating pressure | 20 psi to 125 psi |

| Operating temperature | 40°F to 110°F |

| Resin volume (cubic feet) | 1.0, 1.5, 2.0, 3.0, 4.0, 7.0 and 10.0 |

| Resin type | 8% crosslinked std. (10% available) |

| Brine tank volume | 240 lbs. (other sizes available) |

| Brine tank overflow | Overflow prevention device Included |

| Model Number | Size Valve | Resin Capacity (Cu. Ft.) | Resin Type | Design Flow Rate (GPM) | Mineral Tank | Brine Tank | Bottom Distributor |

|---|

| SW-WC-300-125 | 1.25” | 3 | 8% | 15-20 | 14X65 | 18X36 | Riser and basket |

| SW-WC-400-125 | 1.25” | 4 | 8% | 20-25 | 16X65 | 18X36 | Riser and basket |

| SW-WC -400-150 | 1.5” | 4 | 8% | 25-30 | 16×65 | 18×36 | Hub & laterals |

| SW-WC -700-150 | 1.5” | 7 | 8% | 30-35 | 21×62 | 18×36 | Hub & laterals |

| SW-WC-700-200 | 2” | 7 | 8% | 35-40 | 21×62 | 38×55 | Hub & laterals |

| SW-WC-1000-200 | 2” | 10 | 8% | 40-65 | 24×72 | 38×55 | Hub & laterals |

| SW-WC-2000-200 | 2” | 20 | 8% | 40-90 | 36X72 | 38X55 | Hub & laterals |

| SW-WC-3500-300 | 3” | 35 | 8% | 40-95 | 48X72 | 38X55 | Hub & laterals |

| SW-WC-5000-300 | 3” | 50 | 8% | 65-100 | 63X86 | 38X55 | Hub & laterals |